Services

1. Material & Yarn Selection

We support customers by carefully selecting materials based on performance requirements and end-use. Depending on the specification, we can choose between nylon 6, nylon 66, polyester, or other functional fibers, such as:

– Hydrocool (Nan Ya Plastics)

– Shin Cool (Shinkong)

– Coolmax (from Lycra, often available through Taiwanese spinners)

– Far Infrared fibers (various Taiwanese producers)

– Antibacterial yarns (e.g., Silver-ion, Zinc-ion)

– Moisture-wicking fibers from domestic and international suppliers

We also select the correct yarn size (denier) and filament cross-section to meet functional targets for stretch, moisture management, UV protection, or thermal regulation.

2. Knitting Method

Choosing the right knitting structure is key to fulfilling your product objectives. We balance the trade-offs between:

– Fabric stability (less distortion, better shape recovery)

– Mechanical stretch & elasticity (more comfort, more flexibility)

– Air permeability (breathability)

– Production efficiency

For instance, warp knitting offers superior stability and high productivity, while weft knitting allows greater elasticity and pattern versatility. We will work with you to select the best knitting method, from single jersey, interlock, pique, mesh, to warp-tricot, to optimize both functional performance and production feasibility.

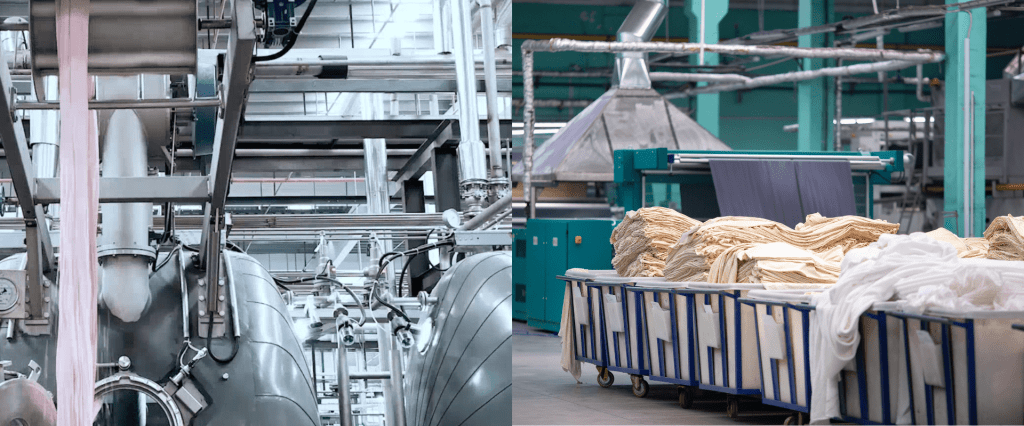

3. Dyeing & Finishing

This stage is critical to a textile’s final quality. Dyeing and heat setting directly impact:

– Hand-feel (softness, bulk, skin comfort)

– Color evenness and fastness (resistance to wash, light, sweat)

– Dimensional stability (shrinkage control)

– Mechanical stretch performance (especially spandex-blended knits)

It is also where small defects originating from yarn or knitting, which may not be noticeable on greige fabric, can become highly visible after dyeing. Therefore, choosing the right dyeing and finishing partners is essential to avoid hidden quality issues and achieve consistent, professional results.

4. Quality Assurance & Support

We back every project with rigorous quality inspection and comprehensive technical guidance. From lab dips and precise color matching, through tests for stretch recovery and dimensional stability, to multi-fiber colorfastness testing and final packaging checks, our team ensures your knitted fabrics meet the highest standards. We are committed to helping brands deliver premium products to their customers with confidence and with consistent quality.